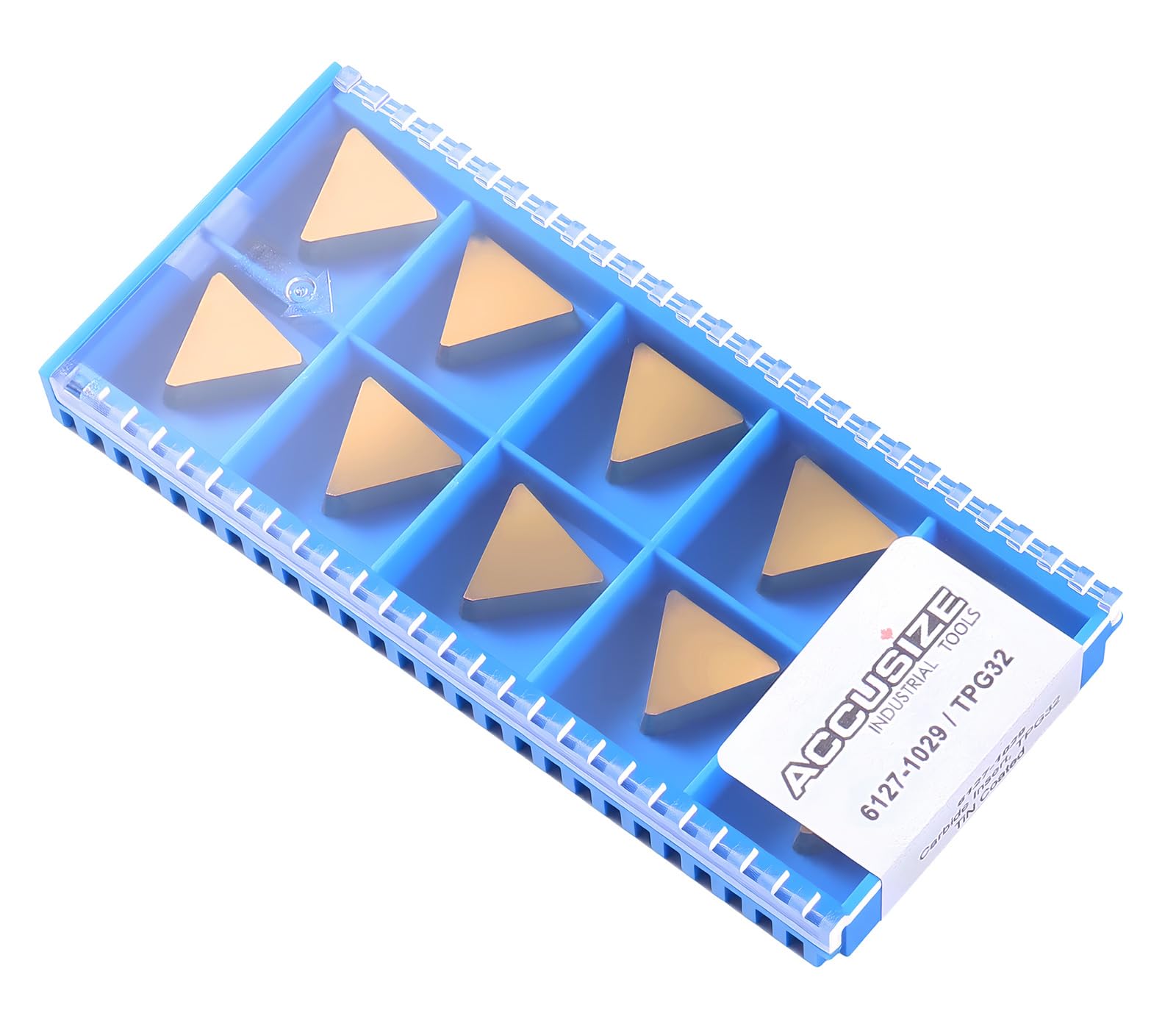

Accusize Industrial Tools TPG32(TPGN1603) Tin Coated Carbide Inserts, T Shaped, 10 Pcs/Box, 2127-1029x10

$39.00

by Accusize Industrial Tools

Shop Now

TPG32; ISO Designation: TPGN16031 TiN Coated Carbide Inserts I.C: 3/8"'; Thickness: 1/8" Sharp edge, no nose radius 10 piece set Precision Crafted Inserts: TPG32 (TPGN1603) carbide inserts with sharp edges for clean, precise cuts. Package includes 10 TiN coated pieces. Optimal Specifications for Detailed Work: Each insert has a 3/8" I.C size and 1/8" thickness, tailored for detailed machining tasks requiring high precision. Durability Enhanced with TiN Coating: Titanium Nitride (TiN) coating provides superior wear resistance, extending tool life and enabling faster machining speeds. Improved Cutting Performance: Positive rake angle and T-shaped design for better cutting clearance and finishes, ensuring inserts sit flat in holders. Robust Design for Versatile Machining: Engineered with larger nose angles and tip radii for a stronger cutting edge, ideal for a variety of materials despite potential for increased vibration and rougher finishes. The Accusize Industrial Tools TPG32 (TPGN1603) TiN Coated Carbide Inserts set (2127-1029x10) represents the epitome of machining excellence, designed to meet the precise needs of professional machinists. This set of 10 T-shaped carbide inserts, engineered to the highest standards with an ISO designation of TPGN1603, is ideal for a wide range of machining operations requiring both accuracy and efficiency. Boasting a 3/8" I.C size and a thickness of 1/8", these inserts are specifically tailored for detailed machining work where precision is paramount. The sharp edges of each insert ensure clean, accurate cuts, enhancing the quality of the machined product. The Titanium Nitride (TiN) coating on each piece not only significantly increases the tool's wear resistance but also permits operations at higher speeds, thus improving productivity and reducing the need for frequent replacements. A notable feature of these inserts is their positive rake angle, coupled with a T-shaped design, which guarantees improved cutting clearance and superior finishes. This design ensures that the inserts sit perfectly flat within their holders, optimizing performance and achieving a high-quality surface finish on workpieces. Moreover, the TPG32 inserts are designed with larger nose angles and tip radii, a strategic choice that results in a stronger cutting edge. While this may introduce increased vibration and potentially rougher finishes under certain conditions, it is a calculated trade-off that ensures these inserts can tackle a variety of materials with ease.